Robots have been revolutionizing the manufacturing industry, reshaping the way products are made and improving efficiency in various processes. This transformation has been driven by advancements in technology, particularly in the fields of robotics and artificial intelligence. As robots continue to evolve, their impact on manufacturing becomes increasingly significant. Let’s delve into how robots are transforming the manufacturing landscape.

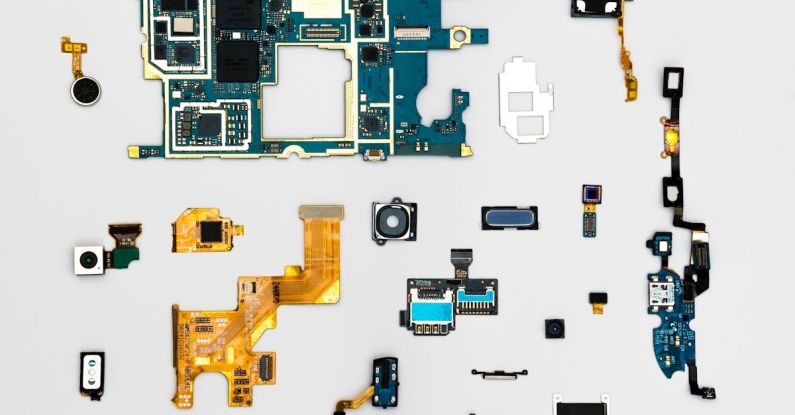

Automation in Production Lines

One of the primary ways robots are transforming manufacturing is through automation in production lines. Traditional manufacturing processes often involved manual labor, which could be time-consuming and prone to errors. With the introduction of robots, tasks that were once performed by humans can now be executed with precision and speed. Robots are capable of handling repetitive tasks with consistency, leading to increased productivity and reduced labor costs for manufacturers.

Improved Quality Control

Robots are also playing a crucial role in enhancing quality control in manufacturing. By utilizing sensors and advanced monitoring systems, robots can detect defects and abnormalities in products more effectively than human workers. This results in a higher level of product quality and consistency, ultimately leading to increased customer satisfaction. Additionally, robots can perform inspections at a much faster rate, allowing manufacturers to identify and address issues promptly.

Flexible Manufacturing Processes

The flexibility of robots in manufacturing processes is another key aspect of their transformative impact. Unlike traditional machinery, robots can be easily reprogrammed and adapted to perform different tasks. This flexibility enables manufacturers to quickly switch between product lines or make adjustments to meet changing market demands. As a result, companies can stay agile and responsive in a rapidly evolving industry landscape.

Enhanced Safety in the Workplace

Safety is a top priority in manufacturing environments, and robots are contributing significantly to improving workplace safety. By taking over hazardous tasks or working in dangerous conditions, robots help reduce the risk of injuries to human workers. This not only ensures a safer work environment but also boosts employee morale and overall efficiency. With robots handling tasks that pose potential risks, workers can focus on more complex and strategic aspects of the manufacturing process.

Integration of Artificial Intelligence

The integration of artificial intelligence (AI) into robotics is further propelling the transformation of manufacturing. AI-powered robots can analyze data in real-time, make autonomous decisions, and adapt to changing circumstances. This level of intelligence enables robots to optimize production processes, identify patterns for predictive maintenance, and continuously improve performance. As AI continues to advance, robots will become even more sophisticated in their capabilities, driving further innovation in manufacturing.

Cost-Efficiency and Scalability

Robots offer significant cost-efficiency benefits for manufacturers, particularly in terms of long-term savings. While the initial investment in robotics technology may be substantial, the operational costs and maintenance expenses are often lower than those associated with human labor. Moreover, robots can scale production capabilities more easily than human workers, allowing manufacturers to ramp up or down production as needed without significant overhead costs. This scalability is particularly valuable in meeting fluctuating market demands and optimizing production efficiency.

A Glimpse into the Future of Manufacturing

Looking ahead, the future of manufacturing holds immense potential with robotics at its core. As technology continues to evolve, robots will become more intelligent, agile, and collaborative in working alongside human operators. The integration of advanced technologies such as 5G connectivity, Internet of Things (IoT), and augmented reality will further enhance the capabilities of robots in manufacturing. This ongoing transformation will not only drive operational efficiency and cost savings but also pave the way for new opportunities and innovations in the industry.

In conclusion, robots are undeniably transforming the manufacturing landscape, ushering in a new era of automation, efficiency, and innovation. With their ability to automate tasks, improve quality control, enhance flexibility, ensure workplace safety, integrate artificial intelligence, and drive cost-efficiency and scalability, robots are reshaping the way products are made and setting the stage for the future of manufacturing. Embracing this transformative technology will be key for manufacturers to stay competitive and thrive in an increasingly dynamic and demanding market environment.